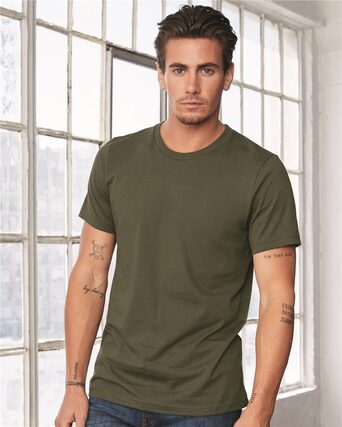

Why Gildan T-Shirts are the Best Option for Bulk PurchasesIMAGES VIA GILDAN IMAGE VIA IMAGE VIA Buying in Bulk If you're looking to buy t-shirts in bulk, Gildan should be on your radar. Because of their low prices and large quantity options, Gildan t-shirts are a cost-effective option for anyone in need of a large number of shirts. Low Cost The low cost of Gildan t-shirts is one of the main reasons why they are so popular among those looking to buy in bulk. Gildan t-shirts are significantly less expensive than other brands, making it possible to buy a large number of shirts without breaking the bank. This is particularly useful for companies, organizations, and events that require a large number of shirts for employees, volunteers, or participants. Wide Variety of Styles However, just because Gildan t-shirts are inexpensive does not imply that they are of poor quality. Gildan t-shirts are 100% cotton and come in a variety of styles, including short sleeve, long sleeve, and hooded options. They also come in a variety of colors, so you're bound to find one that suits you, your company, and/or organization. Range of Sizes Another benefit of Gildan t-shirts is the wide range of sizes available. They have sizes for all ages, from infants to adults. This makes it simple to order shirts for a wide range of people without worrying about finding the right size for everyone. In conclusion... Gildan t-shirts are a low-cost, high-quantity option for anyone looking to buy t-shirts in bulk. Gildan t-shirts are a versatile and practical choice for any occasion, thanks to their low prices, wide range of styles, sizes, and colors, and ability to customize the shirts with your own design.

1 Comment

Your Brand

Ink / Method of PrintingThe type of ink you plan on using can also play a factor in picking the perfect t-shirt as well as the printing method, such as DTG (direct to garment printing), screen print or vinyl. Why can ink play a factor? Sometimes the inks react differently to the garment of shirts. For example, sometimes screen printing neon inks do not react well to polyester blend t-shirts. Some t-shirt blends need to be cured (dried) more than others after screen printing to prevent the ink from cracking after a few washes. The method of printing can also play a big factor. Like the inks, the method of printing may need a particular style of t-shirt. We've learned that for screen printing, most garments are O.K. for production, but if you're considering DTG we've learned that, to maximize the print quality, it is better to use 100% cotton on ringspun cotton. Apparel FittingLastly, and maybe the most important consideration in choosing the perfect t-shirt is---How does the shirt fit?!? This is why it is recommended to order a few samples to wear them around, wash, and see how they react after that. Does the sleeves shrink? Does the shirt shrink? Does it fit the same? Did the color fade? By ordering samples, you will know exactly what you're selling/what your client is receiving/what your employees, friends or family will be wearing. Don't let picking a t-shirt prevent you from getting your vision to the world! We will help you from start to finish. Click the button below to get started on your project today! Ready to start your project with us?Things You Need To Know About Preparing Artwork For Screen PrintingWe would like to simplify the process for our customers and help you out, so please send us an email or give us a call and we can walk you through the process. :) This post is a guide on some things to think about and the requirements we need from you to prepare artwork files for screen printing at Leo’s Silk Screen Service. Learn how to prepare your artwork files for screen printing! When preparing your custom artwork for printing on apparel, other garments or material, you must take a few things into consideration to ensure it will print properly. Preparing Your Design

Example of a full-color vector design and color separation: File Formats All digital files we use for screen printing end up in vector format in order to print with our setup. Typically, we ask for artwork in PDF or Illustrator (.ai) formats - and NOT just pasted into Illustrator and sent as a .ai file. All files must be at least 300dpi or vector format. We need true vector formats that are smooth shapes/edges that can infinitely be scaled up or down with no image quality loss. We accept the following File Types:

Outlining text Outlining text Convert Your Text to Outlines If fonts are in your artwork, please be sure to outline the font before sending the file as we may not have the specific file on our computers. Outlining the text prevents this from being an issue. Sizing Artwork Send your artwork at the size you want it printed. When opening the file, and it opens at 11" wide, we will know you want it printed at 11" wide.  Mockup Your Apparel / Material You may want to mockup your design first so you can get an idea of what it will look like on a shirt. At Leo's Silk Screen, we'll send over a final proof/mockup to make sure you're apparel/project will be printed exactly the way you imagined it to come out! Download our free t-shirt mockup template!

RECAP

For Frequently Asked QuestionsRefer to Leo’s Silk Screen Service’s Terms & Condition for more information.

Please don't hesitate to reach out to us to help guide you! [email protected] Call us (323) 266-2910 Screen Printing 101 @ Leo's Silkscreen ServiceAs a customer, sometimes you wonder, “HOW DO THEY DO IT?”. Well, we thought we’d put together a 101 on screen printing to educate our customers. The technical term for screen printing is “serigraphy”. Screen printing is also known as “silk screening”. It is the process of pressing ink through a fine mesh screen and the screen will allow ink to pass through in certain areas and will block it in others. The screen printing technique was first used by the Chinese nearly thousands of years ago. The Japanese adopted the screen printing process using woven silk to create the mesh. Silk has not been used commonly as they used to, but polyester has been used since the 1940s and is by far the most common type of screen mesh used today. Let’s go over some basic fundamentals of making a print… Artwork

It starts with an idea, then comes artwork. The artwork is then converted into a digital format. Designs are converted dark black before getting outputted onto a film, no matter what color your designs are. Therefore, multiple color designs need to be separated by color and a film positive will be made for each color. Film So---The design is then outputted onto a film positive. Film positives are opaque sheets, similar to transparency sheets. The design must be dark enough so that it blocks UV light from the exposure unit to the areas behind the design. Screens Screens come in different sizes and mesh counts. Mesh is the fabric stretched over the screen’s frame and the mesh count is the tiny holes in it. Understanding what screen mesh to use for particular detail in designs and fabric is important as it determines the amount of ink laid down. We’ll dedicate an entire article in the next few weeks as talking about screens can be another article in itself. Emulsion OK---Artwork, design, film output, screens, what’s next? Emulsion. Before the films and screens get burned by the exposure unit (UV light), the screens need to be coated in emulsion and dried. The emulsion is a thick liquid substance which reacts to light. The emulsion is applied to the screen. Once the screen is coated, the screen is kept in darkness. Any light could start exposing the screen. When you expose the screen to light, since the emulsion is photosensitive, the light causes the emulsion to harden and bind to the screen. Burning Now, that the film is ready to be burned into the emulsion-coated screen, burning the screen (using UV light), the light exposes the design emulsion, hardening it into the screen everywhere except under the design of the film, which was protected by the light. The Wash After exposing the screen to light, we remove the film and wash out the screen, and we now have our design stencil. Load The Platen(s)! Platens are the plates or a flat platform where we lay the shirts on and clamp the screens. This is where we make sure the screen and design will align with the shirt properly. Screen Printing Let the screen printing begin: Ink is then placed at the top/bottom of the screen, making sure the ink will fill the design stencil. This is process is called “flood stroke”. Once we’re good to go, holding a squeegee, we pull the squeegee over the design. Lifting up the screen, we check to see if the shirt has a good layer of ink spread evenly. The shirt/fabric is then dried by a flash cure unit. Flash cure units use infrared heat to dry the ink to the touch quickly so that it may receive another layer of the ink or new ink color in multiple color designs. Viola! The print run is done and now you know how screen printing is done! Of course, there are tons of knowledge absent in this article, but here at Leo’s Silkscreen Service, we hope you know that you are in good hands. We’ve dealt with all sorts of materials and product. Once upon a time, Leo’s Silkscreen Service was solely a silk screen manufacturer in the Los Angeles area. Now, we are a full-service, creative, screen printing company with no-minimum to mass production capabilities. With our years of experience and knowledge, you get the only the best of the best. Let us know how we can help you. Email us: [email protected]. |

AuthorLeo's Silkscreen Service, Inc. Archives

January 2023

Categories

All

|

|

TERMS & CONDITIONS

© COPYRIGHT 2017 LEOSUSA.COM. ALL RIGHTS RESERVED. |

RSS Feed

RSS Feed